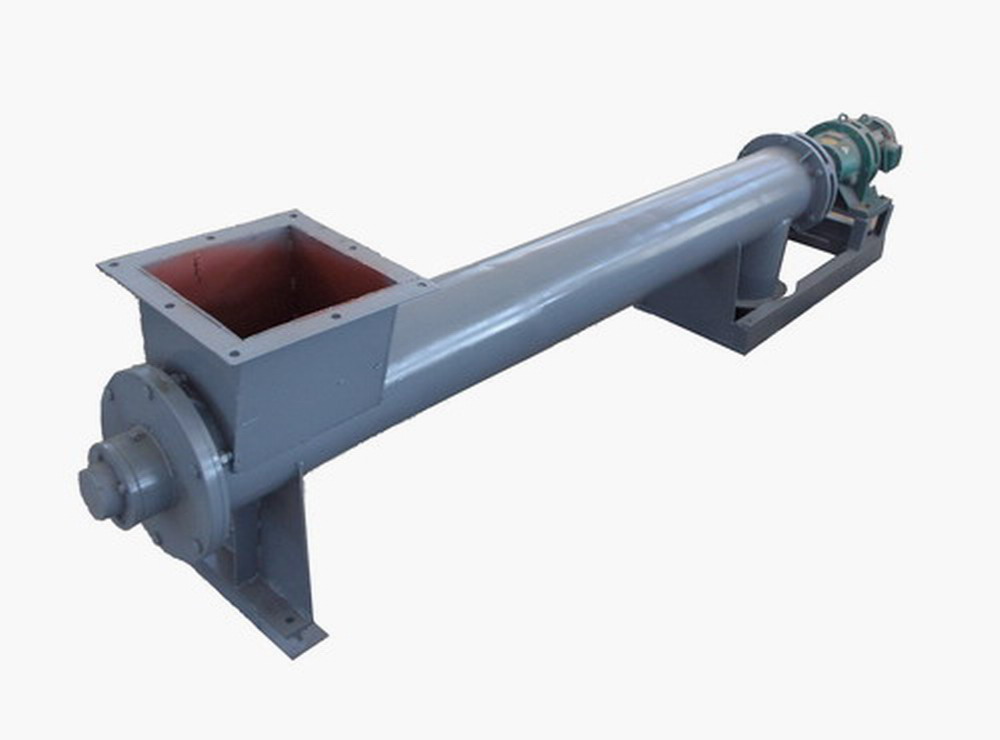

螺旋输送机产品概述

螺旋输送机在输送形式上分为有轴螺旋输送机和无轴螺旋输送机两种,在外型上分为U型螺旋输送机和管式螺旋输送机。有轴螺旋输送机适用于无粘性的干粉物料和小颗粒物料.(例如:水泥、粉煤灰、石灰、粮等)而无轴螺旋输送机适合输送机由粘性的和易缠绕的物料。(例如:污泥、生物质、垃圾等)螺旋输送机的工作原理是旋转的螺旋叶片将物料推移而进行螺旋输送机输送,使物料不与螺旋输送机叶片一起旋转的力是物料自身重量和螺旋输送机机壳对物料的摩擦阻力。螺旋输送机旋转轴上焊的螺旋叶片,叶片的面型根据输送物料的不同有实体面型、带式面型、叶片面型等型式。螺旋输送机的螺旋轴在物料运动方向的终端有止推轴承以随物料给螺旋的轴向反力,在机长较长时,应加中间吊挂轴承。

Product overview

Screw conveyor in the conveying form into a shaft screw conveyor and shaftless screw conveyor, on the exterior is divided into U tube and screw conveyor and screw conveyor.A shaft screw conveyor is suitable for the non-adhesive powder material and small particle material. (such as cement, fly ash, lime, food, etc.) without shaft screw conveyor is suitable for the material conveyor by viscous and winding.(e.g., sludge, biomass, waste, etc.) the working principle of screw conveyor is rotating spiral blade for screw conveyor conveying the material goes on, the material is not spinning force with the blades of screw conveyor is its own weight and screw conveyor casing material friction resistance of the material.Screw conveyor on the axis of rotation welding of spiral vane, the face of the blade type according to the different type has a solid surface of conveying material, belt type, such as blade surface type.Screw conveyor screw axis of the terminal at the direction of material movement have thrust bearings to the material to spiral axial reaction force, the captain is longer, should add hanging bearing in the middle.

螺旋输送机的分类

螺旋输送机从输送物料位移方向的角度划分,螺旋输送机分为水平式螺旋输送机和垂直式螺旋输送机两大类型。

按输送链采用高强度塑料制作的螺旋输送机又称为食品螺旋输送机,螺旋提升机,主要适用于输送大件产品。如纸箱,周转箱,桶装水等。

根据输送物料的特性要求和结构的不同,螺旋输送机有水平螺旋输送机、垂直螺旋输送机、可弯曲螺旋输送机、螺旋管(滚筒输送机)输送机。

(1)垂直螺旋输送机

垂直螺旋输送机的螺旋体的转速比普通螺旋输送机的要高,加入的物料在离心力的作用下,与机壳间产生了摩擦力,该摩擦力阻止物料随螺旋叶片一起旋转并克服了物料下降的重力,从而实现了物料的垂直输送。该机输送量小,输送高度小,转速较高,能耗大。特别适宜输送流动性好的粉粒状物料,主要用于提升物料,提升高度一般不大于8米。

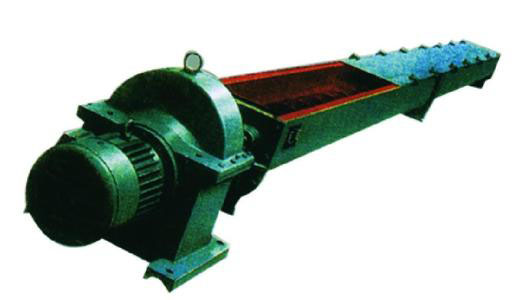

(2)水平螺旋输送机

当物料加入固定的机槽内时,由于物料的重力及其与机槽间的摩擦力作用,堆积在机槽下部的物料不随螺旋体旋转,而只在旋转的螺旋叶片推动下向前移动,如同不旋转的螺母沿着转动的螺杆作平移运动一样,达到输送物料的目的。该机便于多点装料与卸料,输送过程中可同时完成混合、搅拌或冷却功能。对超载敏感,易堵塞;对物料有破碎损耗,水平螺旋输送机的结构简单,便于安装和维修以及故障处理。适用于水平或微倾斜(20º以下)连续均匀输送松散物料,工作环境温度为-20—+40℃,输送物料温度为-20—+80℃。其转速相对于垂直输送机要低,主要用于水平或小倾角输送物料,输送距离一般不大于70米。

(3)螺旋管(滚筒输送机)输送机

螺旋管输送机是在圆筒形机壳内焊有连续的螺旋叶片,机壳与螺旋叶片一起转动。加入的物料由于离心力和摩擦力的作用随机壳一起转动并被提升后,在物料的重力作用下又沿螺旋面下滑,使物料随螺旋管一起旋转从而实现了物料的向前移动,如同不旋转的螺杆沿着转动的螺母作平移运动一样,达到输送物料的目的。

该机能耗低,维修费用低;在端部进料时,能适应不均匀进料要求,可同时完成输送搅拌混合等各种工艺要求,物料进入过多时也不会产生卡阻现象;便于多点装料与卸料,可输送温度较高的物料。适宜于水平输送高温物料;对高温、供料不均匀、有防破碎要求、防污染要求的物料和需多点加卸料的工艺有较好的适应性。实践证明,在输送水泥熟料、干燥的石灰石、磷矿石、钛铁矿粉、煤和矿渣等物料时效果良好。

由端部进料口加入的物料,其粒度不能大于1/4的螺旋直径;自中间进料口加料的物料,其粒度均不得大于30毫米。为保证筒体不产生变形,加料温度必须控制在300℃以下。该机在输送磨琢性大的物料时对叶片和料槽的磨损极为严重。本次所设计的螺旋输送机主要用与输送硅微粉其磨琢性很大所以不适宜采用螺旋管输送机。

(4)可弯曲螺旋输送机

该机螺旋体心轴为可挠曲的,因此输送线路可根据需要按空间曲线布置。根据布置线路中水平及垂直(大倾角)段的长度比例不同,其工作原理按普通螺旋输送机或垂直螺旋输送机设计。

用于输送线路需要按空间曲线任意布置,避免物料转载的场合;当机壳内进入过多的物料或有硬块物料时,螺旋体会自由浮起,不会产生卡堵现象;噪音小。主要用于同时完成物料的水平和垂直输送。垂直输送时一般要求转速要高不能低于1000r/min。

classification

Screw conveyor divided from the Angle of conveying material displacement direction, screw conveyor is divided into horizontal screw conveyor and two types of vertical screw conveyor.

According to the conveying chain made of high strength plastic screw conveyor, screw conveyor is also known as food spiral winding machine, mainly suitable for conveying bulk products.Such as carton, turnover box, bottled water, etc.

According to the requirements of the conveying material properties and structure of different screw conveyor has a horizontal screw conveyor, vertical screw conveyor, flexible screw conveyor, screw conveyor, roller conveyor).

(1) the vertical screw conveyor

Vertical screw conveyor of the helix speed is higher than ordinary screw conveyor, to join the material under the action of centrifugal force, between the casing and the friction, the friction block material with spiral blade rotation and to overcome the gravity drop of material, so as to realize the vertical transportation of the material.Small machine throughput is small, high, high speed, large energy consumption.Especially suitable for conveying liquid, powder and granular materials are mainly used for lifting materials, hoisting height is generally not more than 8 meters.

(2) the horizontal screw conveyor

When material into fixed in slot machine, due to the gravity of the material and its effect and the friction between the slot machine, piling up in machine a material at the bottom of the tank does not rotate with the helix, and only in a rotating helical vane driven to move forward, like not rotating nuts along the rotation of the screw for translational motion, to achieve the purpose of conveying material.This machine is easy to multi-point loading and unloading, transportation process can complete mixing, stirring or cooling functions at the same time.Sensitive to overload, easily blocked;Have a crushing loss for the material, the structure of the horizontal screw conveyor is simple, easy installation and maintenance and troubleshooting.Suitable for horizontal or slightly tilted (below 20 & ordm;) continuous uniform conveying loose materials, working environment temperature is 20 - - + 40 ℃, conveying material temperature is 20 - - + 80 ℃.Its low speed relative to the vertical transmission of confidential, and is mainly used for horizontal or small inclination conveying material, conveying distance is generally not more than 70 meters.

(3) the spiral pipe conveyor, roller conveyor)

Spiral pipe conveyor is inside the cylindrical casing with continuous helical blade, welded casing with spiral blade rotation.Join materials due to the action of the centrifugal force and friction force with casing rotation and promotion, in the material under the action of gravity and slide along the spiral surface, make the material with spiral pipe rotation so as to realize the material to move forward, like not rotating along the rotation of screw nut for translational motion, to achieve the purpose of conveying material.

With low energy consumption, and low maintenance cost.When the end feeding, can adapt to the uneven feed demand, it can be finished at the same time conveying various technological requirements, such as mixing material into too much also won't produce jam phenomenon;Facilitate more loading and unloading, may transport materials at higher temperature.Suitable for horizontal transporting materials in high temperature;With high temperature, uneven feed, shatterproof, pollution prevention requirements of material and the need to add more unloading process has good adaptability.Practice has proved that in the transport of cement clinker, limestone, phosphate rock, dry ilmenite the materials such as coal powder, slag and the result is good.

By the end of inlet to join material, its granularity is not greater than 1/4 screw diameter;Since the middle of inlet feed material, its granularity is not allowed more than 30 mm.In order to ensure the cylinder does not produce deformation, charging temperature must be controlled under 300 ℃.Grinding machine in cut big material of blade and a trough of wear is very serious.By the design of the screw conveyor are mainly transported with silicon powder its grinding cut a lot so not suitable for using spiral pipe conveyor.

(4) flexible screw conveyor

The machine spindle is divided flexure, and therefore transmission line can be according to the need to decorate a space curve.According to the arrangement of lines in the horizontal and vertical (Angle) segment length ratio is different, its working principle according to the ordinary screw conveyor or vertical screw conveyor design.

Used for transmission lines need to be decorated according to the space curve arbitrarily, avoid material reproduced occasions;When inside the casing into too much material or lump material, spiral feel free float, won't produce card blocking phenomenon;The noise is small.It is mainly used for complete material of horizontal and vertical transportation at the same time.In vertical transportation generally requires high speed is not less than 1000 r/min.

螺旋输送机工作原理

当螺旋轴转动时,由于物料的重力及其与槽体壁所产生的摩擦力,使物料只能在叶片的推送下沿着输送机的槽底向前移动,其情况好像不能旋转的螺母沿着旋转的螺杆作平移运动一样。物料在中间轴承的运移,则是依靠后面前进着的物料的推力。所以,物料在输送机中的运送,完全是一种滑移运动。为了使螺旋轴处于较为有利的受拉状态,一般都将驱动装置和卸料口安放在输送机的同一端,而把进料口尽量放在另一端的尾部附近。 旋转的螺旋叶片将物料推移而进行输送,使物料不与螺旋输送机叶片一起旋转的力是物料自身重量和螺旋输送机机壳对物料的摩擦阻力。叶片的面型根据输送物料的不同有实体面型、带式面型、叶片面型等型式。螺旋输送机的螺旋轴在物料运动方向的终端有止推轴承以随物料给螺旋的轴向反力,在机长较长时,应加中间吊挂轴承。

Working principle

When the screw axis rotation, due to the gravity of the material and the tank wall solutions generated by friction, make the material only under the push of blade groove bottom along the conveyor moving forward, the situation can't seem to rotate the nut along the rotation of the screw for translational motion.Material bearing in the middle of the migration, it is depend on the materials go forward thrust behind.So, the material of the conveyor transport, completely is a kind of sliding motion.In order to make the screw axis in a favourable state of tension, the general will drive and with the end of the discharging mouth on the conveyor, and near to the end of the feeding port on the other side as far as possible.Rotating spiral blade for conveying the material goes on, the material is not spinning force with the blades of screw conveyor is its own weight and screw conveyor casing material friction resistance of the material.Blade surface type according to the conveying material has the entity type, belt type, leaf surface type and model.Screw conveyor screw axis of the terminal at the direction of material movement have thrust bearings to the material to spiral axial reaction force, the captain is longer, should add hanging bearing in the middle.

螺旋输送机的技术特点

由驱动装置封闭槽箱和螺旋组成借螺旋转动将槽箱内的煤推移输出。

的特点是:结构简单、横截面尺寸小、密封性好、工作可靠、制造成本低,便于中间装料和卸料,输送方向可逆向,也可同时向相反两个方向输送。输送过程中还可对物料进行搅拌、混合、加热和冷却等作业。通过装卸闸门可调节物料流量。但不宜输送易变质的、粘性大的、易结块的及大块的物料。输送过程中物料易破碎,螺旋及料槽易磨损。单位功率较大。使用中要保持料槽的密封性及螺旋与料槽间有适当的间隙。

垂直螺旋输送机适用于短距离垂直输送。可弯曲螺旋输送机的螺旋由挠性轴和合成橡胶叶片组成,易弯曲,可根据现场或工艺要求任意布置,进行空间输送。螺旋输送机叶片有现拉式和整拉失,现拉式可做成任意厚度与规格尺寸,整拉式不宜制作非标准螺旋。

从输送物料位移方向的角度划分,洪泰螺旋输送机分为水平式螺旋输送机和垂直式螺旋输送机两大类型,主要用于对各种粉状、颗粒状和小块状等松散物料的水平输送和垂直提升,该螺旋输送机不适宜输送易变质、粘性大、易结块或高温、怕压、有较大腐蚀性的特殊物料。

螺旋输送机一般由输送机本体、进出料口及驱动装置三大部分组成;螺旋输送机的螺旋叶片有实体螺旋面、带式螺旋面和叶片螺旋面三种形式,其中,叶片式螺旋面应用相对较少,主要用于输送粘度较大和可压缩性物料,这种螺悬面型,在完成输送作业过程中,同时具有并完成对物料的搅拌、混合等功能。

螺旋输送机与其它输送设备相比,具有整机截面尺寸小、密封性能好、运行平稳可靠、可中间多点装料和卸料及操作安全、维修简便等优点。

Characteristic

Its consists of driving gear closed slot box and spiral borrow screw rotation will slot in the course of coal output.

The features are: simple structure, small cross section size, good sealing, reliable operation, low manufacturing cost, convenience of intermediate loading and unloading, transportation direction can reverse, can also be transmitted at the same time two opposite direction.But also for material in the process of conveying stirring, mixing, heating and cooling operations.Through the loading and unloading valve material flow can be adjusted.But unfavorable transportation of perishable, big viscosity, easy to agglomerate and chunks of material.Material is easy broken, in the process of conveying screw and chute is easy to wear.Unit power is larger.Used to keep the material in the tank sealing and have adequate clearance between screw and feeding trough.

Vertical screw conveyor is suitable for short distance transport.Flexible screw conveyor of the screw is composed of flexible shaft and synthetic rubber blade, flexible, according to the technological requirements of the scene or any arrangement, space transportation.Blades of screw conveyor has now pull and the loss, now pull can make arbitrary thickness and size, the pull is unfavorable make non-standard spiral.

Division, from the perspective of conveying material displacement direction HongTai screw conveyor is divided into horizontal screw conveyor and two types of vertical screw conveyor, mainly used for the various powder, granulated and small lump of loose materials such as horizontal and vertical ascend, the screw conveyor is not suitable for transporting perishable, big viscosity, easy to agglomerate or high temperature, be afraid of pressure, special material is corrosive.

Screw conveyor by conveyor commonly ontology, in and out of the mouth and drive of three most;Screw conveyor of the screw blade entity helicoid, belt type spiral blades of screw surface and surface three forms, among them, the spiral vane surface application is relatively small, it is mainly used for transporting materials in large viscosity and compressibility of the screw surface type, in complete conveying operation process, at the same time with and complete mixing, mixing of materials, and other functions.

Compared with other transportation equipment, screw conveyor with small cross section size, good sealing performance, stable operation and reliable, can the middle multipoint charging and discharging and safety operation and easy maintenance, etc.

由驱动装置封闭槽箱和螺旋组成借螺旋转动将槽箱内的煤推移输出。

的特点是:结构简单、横截面尺寸小、密封性好、工作可靠、制造成本低,便于中间装料和卸料,输送方向可逆向,也可同时向相反两个方向输送。输送过程中还可对物料进行搅拌、混合、加热和冷却等作业。通过装卸闸门可调节物料流量。但不宜输送易变质的、粘性大的、易结块的及大块的物料。输送过程中物料易破碎,螺旋及料槽易磨损。单位功率较大。使用中要保持料槽的密封性及螺旋与料槽间有适当的间隙。

垂直螺旋输送机适用于短距离垂直输送。可弯曲螺旋输送机的螺旋由挠性轴和合成橡胶叶片组成,易弯曲,可根据现场或工艺要求任意布置,进行空间输送。螺旋输送机叶片有现拉式和整拉失,现拉式可做成任意厚度与规格尺寸,整拉式不宜制作非标准螺旋。

从输送物料位移方向的角度划分,洪泰螺旋输送机分为水平式螺旋输送机和垂直式螺旋输送机两大类型,主要用于对各种粉状、颗粒状和小块状等松散物料的水平输送和垂直提升,该螺旋输送机不适宜输送易变质、粘性大、易结块或高温、怕压、有较大腐蚀性的特殊物料。

螺旋输送机一般由输送机本体、进出料口及驱动装置三大部分组成;螺旋输送机的螺旋叶片有实体螺旋面、带式螺旋面和叶片螺旋面三种形式,其中,叶片式螺旋面应用相对较少,主要用于输送粘度较大和可压缩性物料,这种螺悬面型,在完成输送作业过程中,同时具有并完成对物料的搅拌、混合等功能。

螺旋输送机与其它输送设备相比,具有整机截面尺寸小、密封性能好、运行平稳可靠、可中间多点装料和卸料及操作安全、维修简便等优点。

Consists of driving gear closed slot box and spiral borrow screw rotation will slot in the course of coal output.

The features are: simple structure, small cross section size, good sealing, reliable operation, low manufacturing cost, convenience of intermediate loading and unloading, transportation direction can reverse, can also be transmitted at the same time two opposite direction.But also for material in the process of conveying stirring, mixing, heating and cooling operations.Through the loading and unloading valve material flow can be adjusted.But unfavorable transportation of perishable, big viscosity, easy to agglomerate and chunks of material.Material is easy broken, in the process of conveying screw and chute is easy to wear.Unit power is larger.Used to keep the material in the tank sealing and have adequate clearance between screw and feeding trough.

Vertical screw conveyor is suitable for short distance transport.Flexible screw conveyor of the screw is composed of flexible shaft and synthetic rubber blade, flexible, according to the technological requirements of the scene or any arrangement, space transportation.Blades of screw conveyor has now pull and the loss, now pull can make arbitrary thickness and size, the pull is unfavorable make non-standard spiral.

Division, from the perspective of conveying material displacement direction HongTai screw conveyor is divided into horizontal screw conveyor and two types of vertical screw conveyor, mainly used for the various powder, granulated and small lump of loose materials such as horizontal and vertical ascend, the screw conveyor is not suitable for transporting perishable, big viscosity, easy to agglomerate or high temperature, be afraid of pressure, special material is corrosive.

Screw conveyor by conveyor commonly ontology, in and out of the mouth and drive of three most;Screw conveyor of the screw blade entity helicoid, belt type spiral blades of screw surface and surface three forms, among them, the spiral vane surface application is relatively small, it is mainly used for transporting materials in large viscosity and compressibility of the screw surface type, in complete conveying operation process, at the same time with and complete mixing, mixing of materials, and other functions.

Compared with other transportation equipment, screw conveyor with small cross section size, good sealing performance, stable operation and reliable, can the middle multipoint charging and discharging and safety operation and easy maintenance, etc.

螺旋输送机技术性能及技术参数:

Parameter:

|

规 格

|

主要技术性能

|

驱动装置

|

驱动装置

|

重量

(kg)

|

||||

|

直径

|

长度

(m)

|

产量

(水泥)

t/h

|

转速

min

|

减速机

|

电动机

|

|||

|

型号

|

速比

|

型号

|

功率

(kw)

|

|||||

|

GX200

|

-10

|

9

|

60

|

JZQ250

|

23.34

|

Y90S-4

|

1.1

|

726

|

|

GX200

|

-20

|

9

|

60

|

JZQ250

|

23.34

|

Y90L-4

|

1.5

|

1258

|

|

GX250

|

-10

|

15.6

|

60

|

JZQ250

|

23.34

|

Y100L2-4

|

2.2

|

960

|

|

GX250

|

-20

|

15.6

|

60

|

JZQ250

|

23.34

|

Y100L1-4

|

3

|

1750

|

|

GX300

|

-10

|

21.2

|

60

|

JZQ350

|

23.34

|

Y100L2-4

|

3

|

1373

|

|

GX300

|

-20

|

21.2

|

60

|

JZQ350

|

23.34

|

Y112M-4

|

4

|

2346

|

|

GX400

|

-10

|

51

|

60

|

JZQ400

|

23.34

|

Y132S-4

|

5.5

|

1911

|

|

GX400

|

-20

|

51

|

60

|

JZQ500

|

23.34

|

Y160M-4

|

11

|

2049

|

|

GX500

|

-10

|

87.5

|

60

|

JZQ400

|

23.34

|

Y132M-4

|

7.5

|

2381

|

|

GX500

|

-20

|

87.5

|

60

|

JZQ650

|

23.34

|

Y180M-4

|

18.5

|

5389

|

|

GX600

|

-10

|

134.2

|

45

|

JZQ750

|

23.34

|

Y180L-4

|

22

|

3880

|

|

GX600

|

-10

|

134.2

|

45

|

JZQ850

|

23.34

|

Y250M-4

|

55

|

7090

|

螺旋输送机的型号说明

Models Decription

L S 400*25*50-M1

│ │ │ │ │ └─────── 轴承类别

│ │ │ │ └───────── 选用转速r/min

│ │ │ └────────── 螺旋输送机长度m

│ │ └───────────── 螺旋直径mm

│ └──────────────- S为水平式

└──────────────── L为螺旋

螺旋输送机的应用范围

螺旋机广泛应用于各行业,如建材、化工、电力、冶金、煤矿炭、粮食等行业,适用于水平或倾斜输送粉状、粒状和小块状物料,如煤矿、灰、渣、水泥、粮食等,物料温度小于200℃。螺旋机不适于输送易变质的、粘性大的、易结块的物料。在混凝土搅拌站中,螺旋输送机的作用得到了最大的体现.

Applications

Screw machine widely used in various industries, such as building materials, chemical industry, electric power, metallurgy, coal mine coal, food and other industries, applicable to horizontal or oblique conveying powder, granulated and small lump materials, such as coal, ash, slag, cement, food, etc., the material temperature is less than 200 ℃.Screw machine is not suitable for transportation of perishable materials, big viscosity, easy to agglomerate.In concrete mixing station, the action of the screw conveyor got the biggest reflect.

螺旋输送机的日常维护与管理

螺旋输送机在使用过程中,一定要注意日常的保养维护,这样才会最大程度地跟沙子烘干机配合好,保证生产量及效率,也使设备的使用寿命延长。

(1)应定时向轴承、齿轮和链条等传动件加润滑油。

(2)箱送机停用后,应检查螺旋叶片磨损情况,磨损严重时补焊。

(3)输送量不可过载,否则物料排不出,引起螺旋轴弯曲和箱体涨坏。

(4)输送的介质沮度较高时,应注意箱体的伸缩变化是否自由而无卡着的地方,若有抓紧解决。

(5)输送机在运转中,发出的噪声刺耳时,应打盖检查,排除故障。

Daily maintenance

Screw conveyor in using process, must pay attention to daily maintenance, such ability can maximize the cooperate well with sand dryer, guarantee the production and efficiency, also prolongs the service life of equipment.

(1) should be regularly to the bearings, gears and chains, such as driving a add lubricating oil.

(2) the box to send after the machine stop, should check the spiral blade wear, wear serious when repair welding.

Do not overload (3) the throughput, or the material out, cause the screw axis bending and box up bad.

(4) falling in conveying medium degree is high, should pay attention to body scale change is free and no card place, if you have to solve.

(5) the conveyor in operation, a shrill noise, should cover check, troubleshooting.